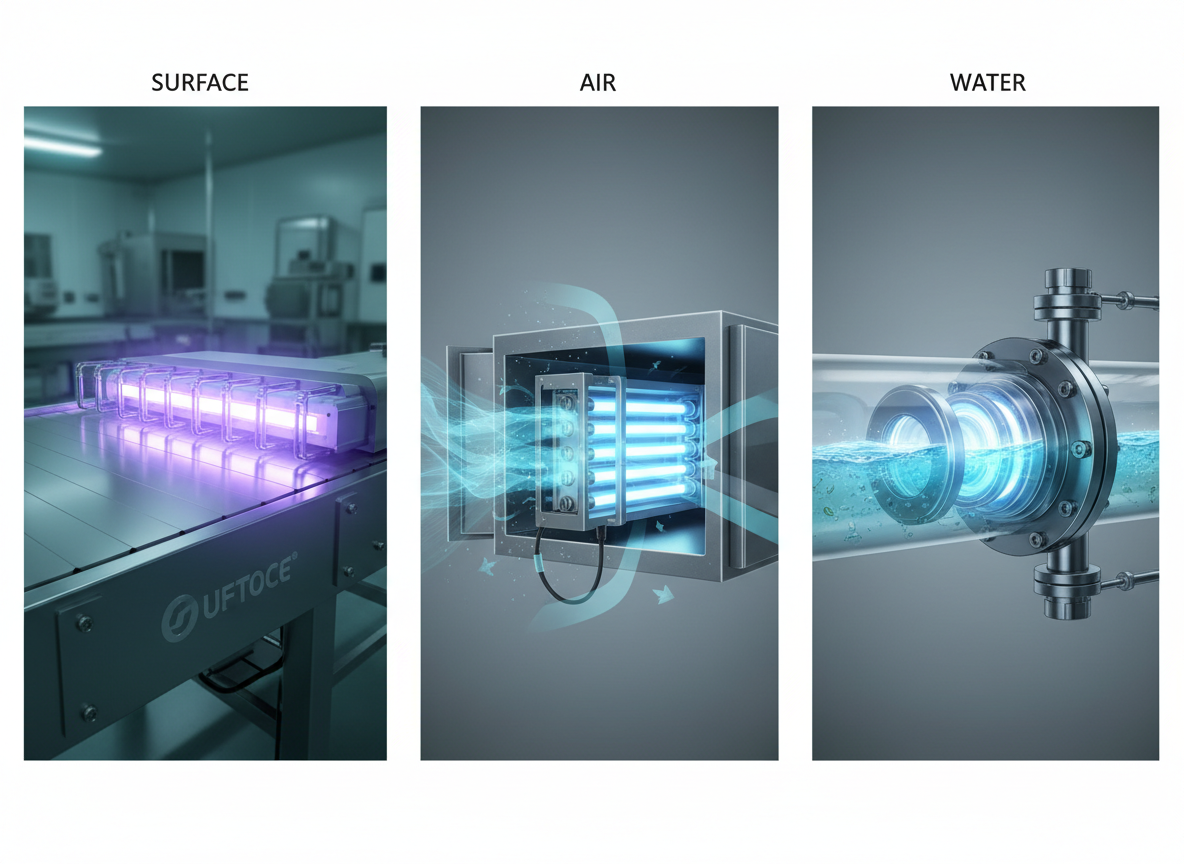

Advanced UVC technology supports decontamination across surface, air, and water treatment. It offers a fast, chemical-free way to reduce microorganisms in healthcare, manufacturing, and public infrastructure.

First Light Lamps manufactures specialised xenon flash lamps in the UK. Since 2004, we have supported OEMs and system integrators that use UVC systems for surface, air, and water treatment.