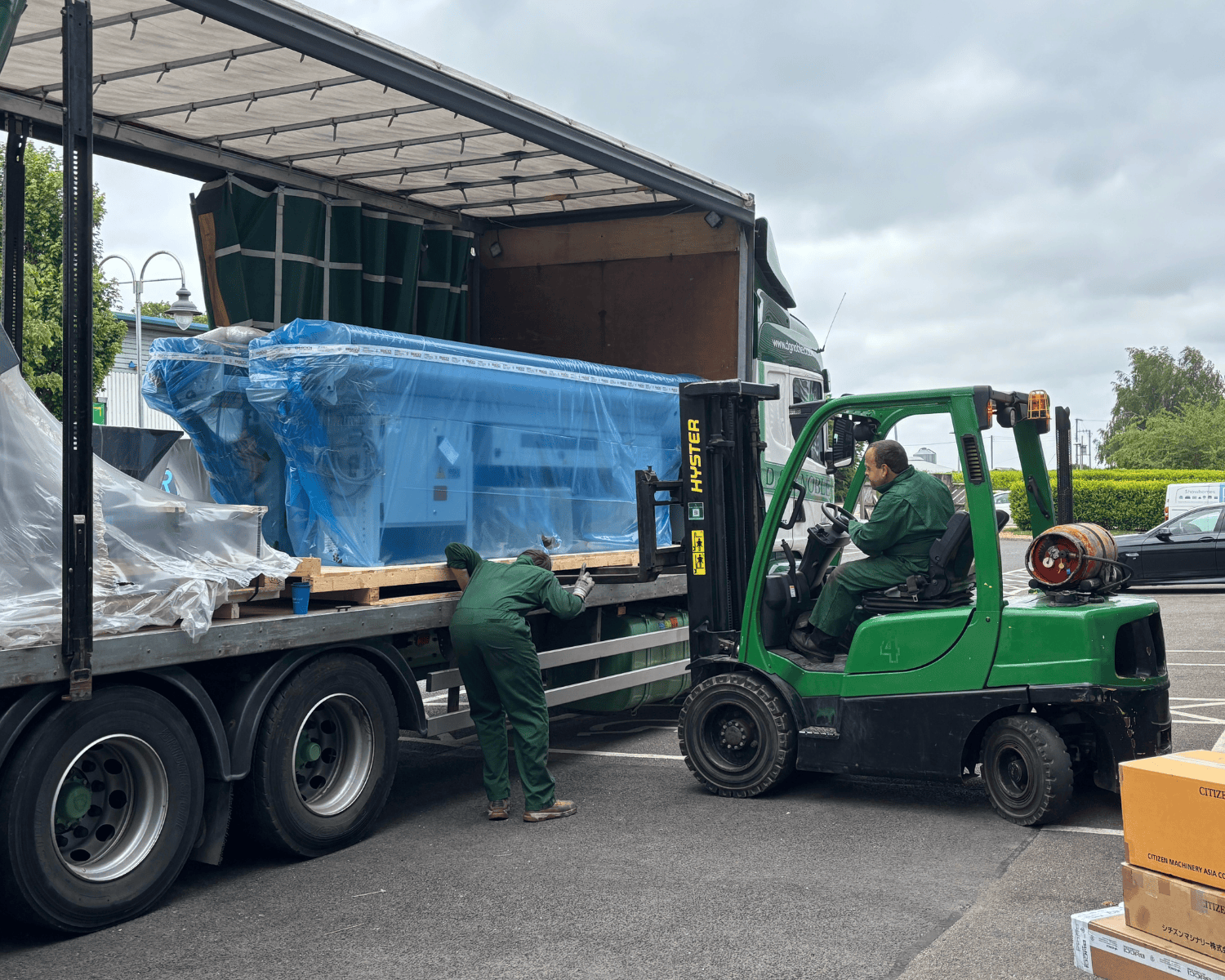

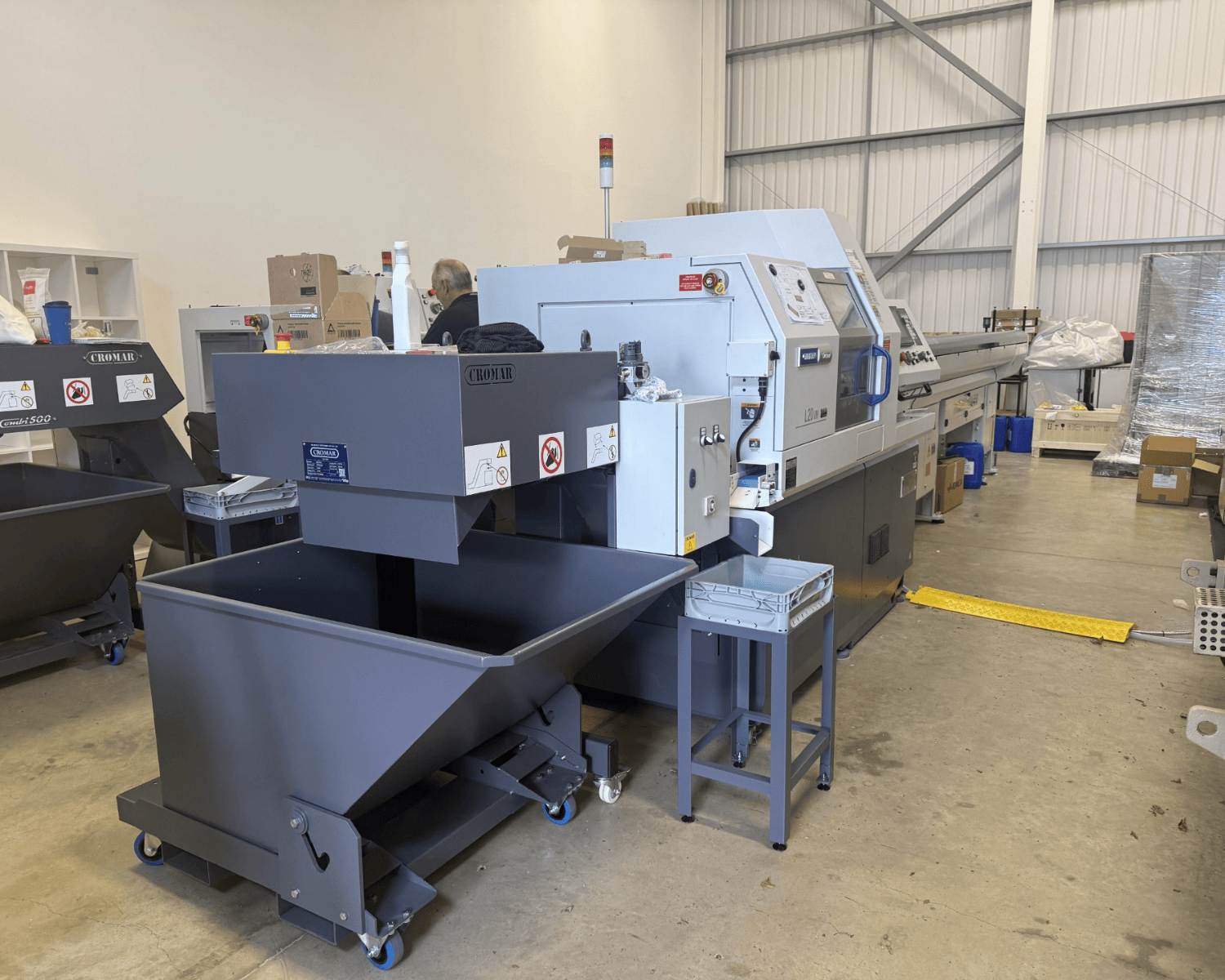

First Light Lamps Ltd are pleased to announce the successful delivery and installation of two state-of-the-art Cincom Citizen Machinery CNC turning centers at our UK manufacturing facility. The L12-VII LFV and L20-VIII LFV machines are now fully operational and already enhancing our production capabilities.

This strategic investment marks a significant milestone in our company’s evolution, representing our largest single technology upgrade since our establishment in 2004. The decision to partner with Cincom Citizen Machinery reflects our commitment to maintaining technological leadership in the specialised flash lamp manufacturing sector.

Precision Engineering Meets Innovation

These Swiss-type CNC turning centers represent a significant investment in our manufacturing future. Both machines feature Cincom Citizen Machinery’s revolutionary Low Frequency Vibration (LFV) technology, which reduces cutting resistance by up to 50% while delivering superior surface finishes – crucial for the precision components required in our xenon and krypton flash lamps.

The L12-VII LFV operates at speeds up to 15,000 RPM with 7-axis simultaneous control, while the L20-VIII LFV handles larger components with the same precision and speed. Together, they can accommodate up to 28 different tools and perform complex multi-axis operations that were previously impossible with our existing equipment.

Advanced Technical Capabilities:

- Simultaneous 7-axis machining enables complex geometries in single setups

- Live tooling capabilities allow milling, drilling, and threading operations

- Sub-spindle functionality provides complete part processing without manual intervention

- Automatic bar feeding systems enable lights-out manufacturing

- Advanced tool management with automatic tool changing and monitoring

The LFV technology is particularly revolutionary for our applications. By synchronizing tool vibration with spindle rotation, it dramatically reduces heat generation during machining – critical when working with the precise tolerances required for flash lamp components. This technology also extends tool life significantly, reducing production costs and ensuring consistent quality across large production runs.